The initial iterations lacked a clear hierarchy, which was later refined based on feedback from supermarket owners.

The initial iterations lacked a clear hierarchy, which was later refined based on feedback from supermarket owners.

The initial iterations lacked a clear hierarchy, which was later refined based on feedback from supermarket owners.

For supermarket owners, we also introduced RefMate, a two-part device with components inside and outside the fridge that attaches easily using a suction cup. It tracks temperature and door status, sending alerts to ensure optimal cold storage.

For supermarket owners, we also introduced RefMate, a two-part device with components inside and outside the fridge that attaches easily using a suction cup. It tracks temperature and door status, sending alerts to ensure optimal cold storage.

For supermarket owners, we also introduced RefMate, a two-part device with components inside and outside the fridge that attaches easily using a suction cup. It tracks temperature and door status, sending alerts to ensure optimal cold storage.

Foresyght demonstrates the potential of technology to solve real, large-scale challenges in food logistics. It is not just a concept but a vision for a more efficient, sustainable, and future-ready supply chain- one that empowers every stakeholder to deliver fresher products, faster, with minimal waste.

This vision was recognised when the project was selected as a finalist at India HCI, IIT Bombay, in November 2024.

AND IT'S A WRAP

Here's Production Manager dashboard ( Gowardhan company was used as example)

Moving on to Distributors

Dashboard was designed for Logistics Manager for efficiency.

Lastly, Manufacturers

Values- Transparency | Confidence | Trust | Relief | Reliability | Efficiency

The logistics manager, operating through the dashboard, handles invoice generation, order allocation, payment oversight, scheduling, dispatching, and real-time monitoring while ensuring clarity on payment terms and coordinating with the sales team. The production manager, focuses on reliable and efficient production scheduling, raw material management, process planning, efficiency improvement, and team coordination.

For Truck Drivers an app in local language was designed

Up next, Transport Providers

Values- Transparency | Monitored

The transport provider, usually the owner of the transport company, uses the dashboard to manage order scheduling and fulfillment, vehicle and staff availability, route planning and tracking, as well as overall order acceptance and delivery. The truck drivers, who carry out the actual transportation, use the app to accept and deliver orders, follow GPS tracking and navigation, and ensure adherence to schedules.

Values- Mutual Benefit | Transparency | Reliability

Key responsibility areas include order fulfillment, inventory management, payment collection, and client relationship management.

A distributor app was introduced as they were always on the move and preferred coordinating through their contacts, making an app a more convenient option for them.

For Transport Providers a dashboard was designed

Starting with Local Supermarket Owner

Values- Accuracy | Reliability | Adaptability

The key responsibility areas include optimizing sales, managing inventory, coordinating with distributors, handling payments and finances, improving operational efficiency, and ensuring customer satisfaction.

These learnings helped us refine our direction and align better with on-ground realities.

What Didn’t Work and Why

Before concept development, we explored early ideas through sketches, low-fi prototypes, and stakeholder feedback. While some seemed promising, real-world testing revealed gaps:

Key Observations

After conducting 20+ in-depth interviews with stakeholders across the supply chain and visiting multiple local supermarkets, we identified four recurring issues. The system is fragmented, with poor temperature control, no expiry tracking, and heavy reliance on manual coordination, leading to product damage, losses, and food wastage.

Pssst…

Looks like a tangled web? Don’t worry let’s untangle it by breaking things down stakeholder by stakeholder.

Pssst…

Looks like a tangled web? Don’t worry let’s untangle it by breaking things down stakeholder by stakeholder.

Pssst…

Looks like a tangled web? Don’t worry let’s untangle it by breaking things down stakeholder by stakeholder.

Meet the Users, up close

❄️ Poor Temperature Control

In humid cities like Mumbai, costly cold storage leads to poor temperature control, causing product damage, equipment wear, and reduced availability for retailers.

⚒️ No Standardized System

There’s no standardized system linking distributors with manufacturers and supermarkets. Many still rely on calls and WhatsApp due to low tech familiarity, despite available software.

⏰ No Expiry Tracking

Supermarkets rely on manual processes, leading to errors and expired products being missed due to limited staff training and lack of tracking software.

🚚 Delivery Mishandling

Improper handling, poor roads, and delivery pressure often damage goods like milk pouches, causing losses for distributors and food wastage.

❄️ Poor Temperature Control

In humid cities like Mumbai, costly cold storage leads to poor temperature control, causing product damage, equipment wear, and reduced availability for retailers.

⚒️ No Standardized System

There’s no standardized system linking distributors with manufacturers and supermarkets. Many still rely on calls and WhatsApp due to low tech familiarity, despite available software.

⏰ No Expiry Tracking

Supermarkets rely on manual processes, leading to errors and expired products being missed due to limited staff training and lack of tracking software.

🚚 Delivery Mishandling

Improper handling, poor roads, and delivery pressure often damage goods like milk pouches, causing losses for distributors and food wastage.

The Reality Behind the Shelf

The perishable food supply chain is riddled with inefficiencies that cost time, money, and quality.

Fragmented Systems 🧩

Disconnected tools lead to delays and zero real-time visibility.Low Tech Adoption ⚙️

Manual processes still rule due to cost and access barriers.Broken Cold Chains 🧊

Poor storage and transport cause high spoilage and waste.

Going back to how it started…

Let's rationalise some of the design decision together!

Dashboard was designed for Logistics Manager for efficiency.

My Role

System design, UX flows, Defining metrics, Primary research, Tech Plan, Data visualization, User testing

The logistics manager, operating through the dashboard, handles invoice generation, order allocation, payment oversight, scheduling, dispatching, and real-time monitoring while ensuring clarity on payment terms and coordinating with the sales team. The production manager, focuses on reliable and efficient production scheduling, raw material management, process planning, efficiency improvement, and team coordination.

AND IT'S A WRAP

Foresyght demonstrates the potential of technology to solve real, large-scale challenges in food logistics. It is not just a concept but a vision for a more efficient, sustainable, and future-ready supply chain- one that empowers every stakeholder to deliver fresher products, faster, with minimal waste.

This vision was recognised when the project was selected as a finalist at India HCI, IIT Bombay, in November 2024.

Here's Production Manager dashboard ( Gowardhan company was used as example)

Values- Transparency | Confidence | Trust | Relief | Reliability | Efficiency

Lastly, Manufacturers

For Truck Drivers an app in local language was designed

Key responsibility areas include order fulfillment, inventory management, payment collection, and client relationship management.

A distributor app was introduced as they were always on the move and preferred coordinating through their contacts, making an app a more convenient option for them.

The transport provider, usually the owner of the transport company, uses the dashboard to manage order scheduling and fulfillment, vehicle and staff availability, route planning and tracking, as well as overall order acceptance and delivery. The truck drivers, who carry out the actual transportation, use the app to accept and deliver orders, follow GPS tracking and navigation, and ensure adherence to schedules.

Values- Transparency | Monitored

Up next, Transport Providers

Values- Mutual Benefit | Transparency | Reliability

Moving on to Distributors

Key Observations

After conducting 20+ in-depth interviews with stakeholders across the supply chain and visiting multiple local supermarkets, we identified four recurring issues. The system is fragmented, with poor temperature control, no expiry tracking, and heavy reliance on manual coordination, leading to product damage, losses, and food wastage.

Defining the problem

40% of processed perishables in India go to waste - often due to small, preventable lapses like open fridge doors, delayed deliveries, or missed stock alerts.

Despite digitalization goals for 2030, India's supply chain remains fragmented. What's missing is a unified, real-time system that ensures visibility, coordination, and smart decisions across every step.

Defining the problem

40% of processed perishables in India go to waste - often due to small, preventable lapses like open fridge doors, delayed deliveries, or missed stock alerts.

Despite digitalization goals for 2030, India's supply chain remains fragmented. What's missing is a unified, real-time system that ensures visibility, coordination, and smart decisions across every step.

Defining the problem

40% of processed perishables in India go to waste - often due to small, preventable lapses like open fridge doors, delayed deliveries, or missed stock alerts.

Despite digitalization goals for 2030, India's supply chain remains fragmented. What's missing is a unified, real-time system that ensures visibility, coordination, and smart decisions across every step.

Key Observations

After conducting 20+ in-depth interviews with stakeholders across the supply chain and visiting multiple local supermarkets, we identified four recurring issues. The system is fragmented, with poor temperature control, no expiry tracking, and heavy reliance on manual coordination, leading to product damage, losses, and food wastage.

Here's how it works

Here's how it works

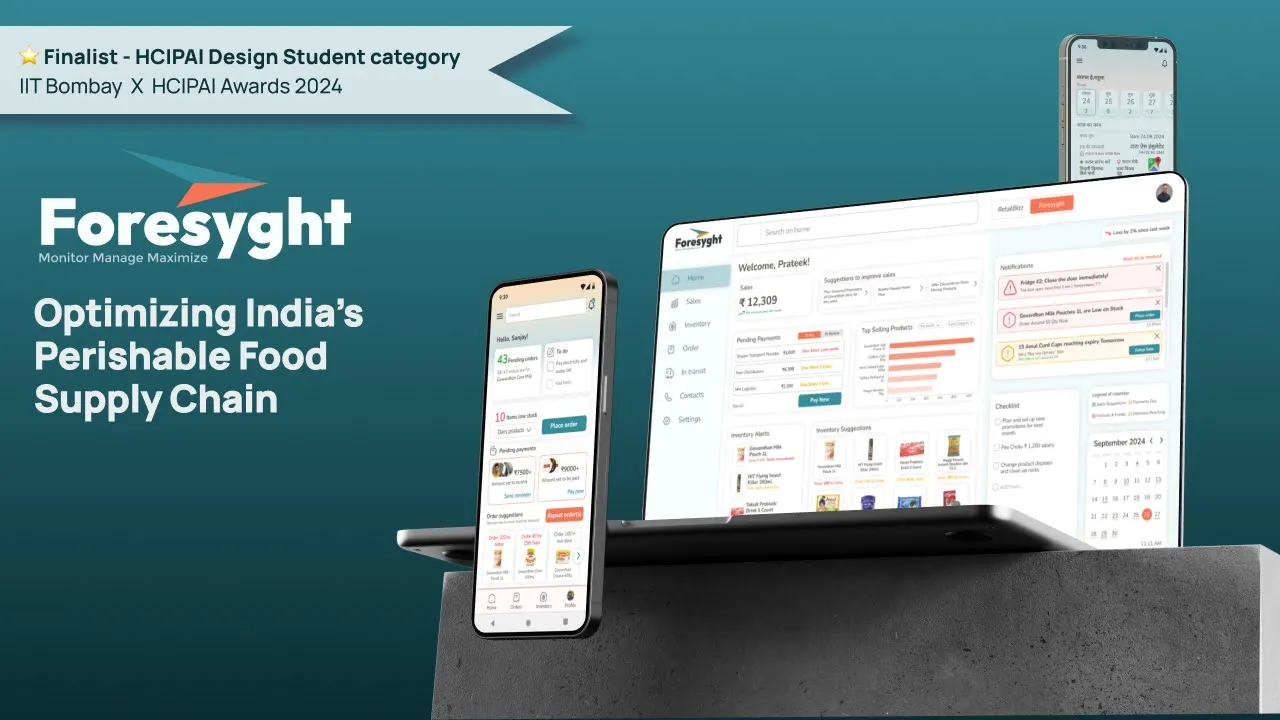

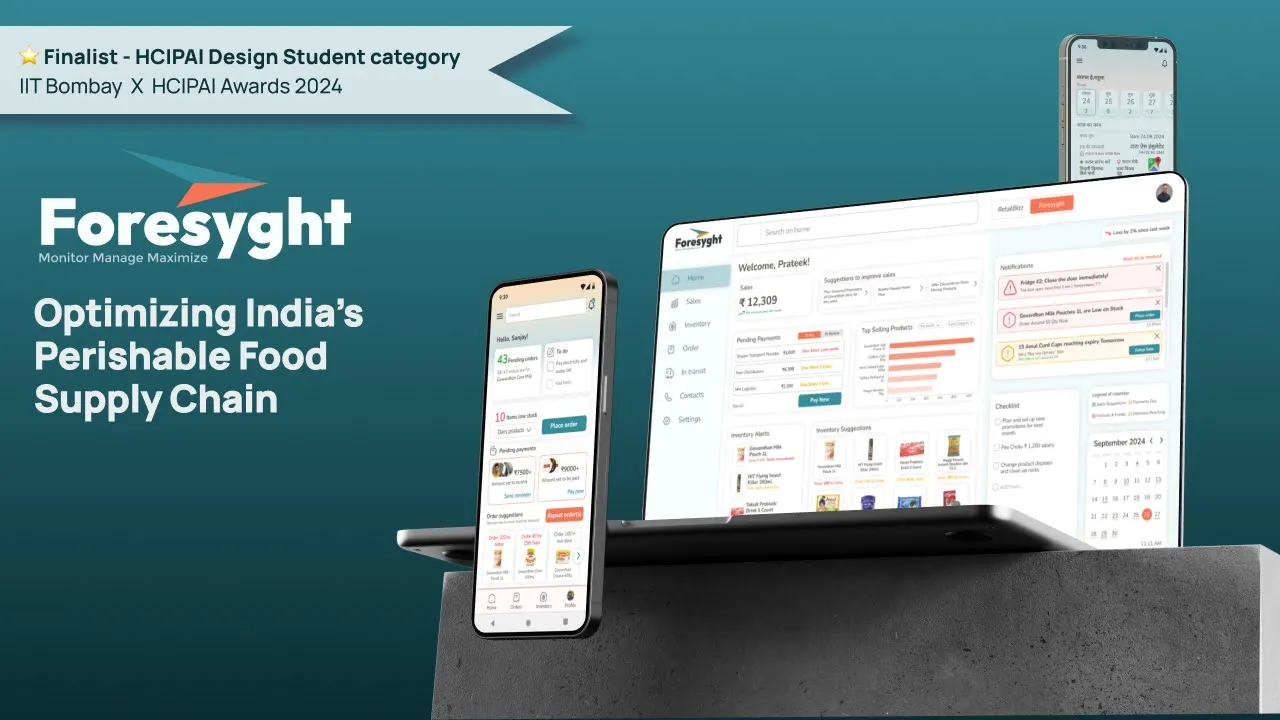

Introducing Foresyght

The key responsibility areas include optimizing sales, managing inventory, coordinating with distributors, handling payments and finances, improving operational efficiency, and ensuring customer satisfaction.

Values- Accuracy | Reliability | Adaptability

Starting with Local Supermarket Owner

What Didn’t Work and Why

Before concept development, we explored early ideas through sketches, low-fi prototypes, and stakeholder feedback. While some seemed promising, real-world testing revealed gaps:

Solution in Action 🚀

Going back to how it started…

Let's rationalise some of the design decision together!

Going back to how it started…

Let's rationalise some of the design decision together!

Wait Let’s Rewind A Bit ⏪

The Reality Behind the Shelf

The perishable food supply chain is riddled with inefficiencies that cost time, money, and quality.

Fragmented Systems 🧩

Disconnected tools lead to delays and zero real-time visibility.Low Tech Adoption ⚙️

Manual processes still rule due to cost and access barriers.Broken Cold Chains 🧊

Poor storage and transport cause high spoilage and waste.

The Reality Behind the Shelf

The perishable food supply chain is riddled with inefficiencies that cost time, money, and quality.

Fragmented Systems 🧩

Disconnected tools lead to delays and zero real-time visibility.Low Tech Adoption ⚙️

Manual processes still rule due to cost and access barriers.Broken Cold Chains 🧊

Poor storage and transport cause high spoilage and waste.

Meet the Users, up close

Meet the Users, up close

These learnings helped us refine our direction and align better with on-ground realities.

Solution in Action 🚀

Solution in Action 🚀

Key Observations

After conducting 20+ in-depth interviews with stakeholders across the supply chain and visiting multiple local supermarkets, we identified four recurring issues. The system is fragmented, with poor temperature control, no expiry tracking, and heavy reliance on manual coordination, leading to product damage, losses, and food wastage.

What Didn’t Work and Why

Before concept development, we explored early ideas through sketches, low-fi prototypes, and stakeholder feedback. While some seemed promising, real-world testing revealed gaps:

These learnings helped us refine our direction and align better with on-ground realities.

Introducing Foresyght

Foresyght transforms the supply chain with real-time tracking, AI forecasts, and seamless stakeholder communication. It ensures precision and efficiency from start to finish.

More than management - it's the future of logistics.

Foresyght transforms the supply chain with real-time tracking, AI forecasts, and seamless stakeholder communication. It ensures precision and efficiency from start to finish.

More than management - it's the future of logistics.

Foresyght transforms the supply chain with real-time tracking, AI forecasts, and seamless stakeholder communication. It ensures precision and efficiency from start to finish.

More than management - it's the future of logistics.

Here's how it works

Starting with Local Supermarket Owner

Values- Accuracy | Reliability | Adaptability

The key responsibility areas include optimizing sales, managing inventory, coordinating with distributors, handling payments and finances, improving operational efficiency, and ensuring customer satisfaction.

❄️ Poor Temperature Control

In humid cities like Mumbai, costly cold storage leads to poor temperature control, causing product damage, equipment wear, and reduced availability for retailers.

⚒️ No Standardized System

There’s no standardized system linking distributors with manufacturers and supermarkets. Many still rely on calls and WhatsApp due to low tech familiarity, despite available software.

⏰ No Expiry Tracking

Supermarkets rely on manual processes, leading to errors and expired products being missed due to limited staff training and lack of tracking software.

🚚 Delivery Mishandling

Improper handling, poor roads, and delivery pressure often damage goods like milk pouches, causing losses for distributors and food wastage.

❄️ Poor Temperature Control

In humid cities like Mumbai, costly cold storage leads to poor temperature control, causing product damage, equipment wear, and reduced availability for retailers.

⚒️ No Standardized System

There’s no standardized system linking distributors with manufacturers and supermarkets. Many still rely on calls and WhatsApp due to low tech familiarity, despite available software.

⏰ No Expiry Tracking

Supermarkets rely on manual processes, leading to errors and expired products being missed due to limited staff training and lack of tracking software.

🚚 Delivery Mishandling

Improper handling, poor roads, and delivery pressure often damage goods like milk pouches, causing losses for distributors and food wastage.

❄️ Poor Temperature Control

In humid cities like Mumbai, costly cold storage leads to poor temperature control, causing product damage, equipment wear, and reduced availability for retailers.

⚒️ No Standardized System

There’s no standardized system linking distributors with manufacturers and supermarkets. Many still rely on calls and WhatsApp due to low tech familiarity, despite available software.

⏰ No Expiry Tracking

Supermarkets rely on manual processes, leading to errors and expired products being missed due to limited staff training and lack of tracking software.

🚚 Delivery Mishandling

Improper handling, poor roads, and delivery pressure often damage goods like milk pouches, causing losses for distributors and food wastage.

Moving on to Distributors

Values- Mutual Benefit | Transparency | Reliability

Key responsibility areas include order fulfillment, inventory management, payment collection, and client relationship management.

A distributor app was introduced as they were always on the move and preferred coordinating through their contacts, making an app a more convenient option for them.

Up next, Transport Providers

Values- Transparency | Monitored

The transport provider, usually the owner of the transport company, uses the dashboard to manage order scheduling and fulfillment, vehicle and staff availability, route planning and tracking, as well as overall order acceptance and delivery. The truck drivers, who carry out the actual transportation, use the app to accept and deliver orders, follow GPS tracking and navigation, and ensure adherence to schedules.

For Transport Providers a dashboard was designed

For Truck Drivers an app in local language was designed

Lastly, Manufacturers

Values- Transparency | Confidence | Trust | Relief | Reliability | Efficiency

The logistics manager, operating through the dashboard, handles invoice generation, order allocation, payment oversight, scheduling, dispatching, and real-time monitoring while ensuring clarity on payment terms and coordinating with the sales team. The production manager, focuses on reliable and efficient production scheduling, raw material management, process planning, efficiency improvement, and team coordination.

Dashboard was designed for Logistics Manager for efficiency.

Here's Production Manager dashboard ( Gowardhan company was used as example)

Foresyght demonstrates the potential of technology to solve real, large-scale challenges in food logistics. It is not just a concept but a vision for a more efficient, sustainable, and future-ready supply chain- one that empowers every stakeholder to deliver fresher products, faster, with minimal waste.

This vision was recognised when the project was selected as a finalist at HCIPAI, IIT Bombay, in November 2024.

AND IT'S A WRAP

My Role

System design, UX flows, Defining metrics, Primary research, Tech Plan, Data visualization, User testing

Key Gaps

Key Gaps

Key Gaps

Team

Vrushti Mehta (hey, that's me!)

Niyati Bhangare

Heramb Kaprekar

Jui Soshte

It began with a single milk packet.

Mildly warm, half-spoiled, and already off the shelf by 11 a.m. at a local store in Andheri.

What caused it?

A fridge left open. A traffic jam. A gut-feel forecast.

We asked: What if this whole journey wasn’t invisible? What if every step was connected, clear, and smart enough to prevent this?

It began with a single milk packet.

Mildly warm, half-spoiled, and already off the shelf by 11 a.m. at a local store in Andheri.

What caused it?

A fridge left open. A traffic jam. A gut-feel forecast.

We asked: What if this whole journey wasn’t invisible? What if every step was connected, clear, and smart enough to prevent this?

It began with a single milk packet.

Mildly warm, half-spoiled, and already off the shelf by 11 a.m. at a local store in Andheri.

What caused it?

A fridge left open. A traffic jam. A gut-feel forecast.

We asked: What if this whole journey wasn’t invisible? What if every step was connected, clear, and smart enough to prevent this?

Team

Vrushti Mehta (hey, that's me!)

Niyati Bhangare

Heramb Kaprekar

Jui Soshte

Team

Vrushti Mehta (hey, that's me!)

Niyati Bhangare

Heramb Kaprekar

Jui Soshte

Team

Vrushti Mehta (hey, that's me!)

Niyati Bhangare

Heramb Kaprekar

Jui Soshte

My Role

System design, UX flows, Defining metrics, Primary research, Tech plan, Data visualization, User testing